Continuous Improvement: Freeze protection requirements and winterization best practices

By Sam Ciccone, Principal Reliability Consultant, Entity Engagement

By Sam Ciccone, Principal Reliability Consultant, Entity Engagement

In this recurring column, I explore improvement opportunities for current industry challenges and ways to continuously improve. I find best practices experienced through entity engagements and research from various sources, and I tie in various continuous improvement methods that have been proven to work across multiple industries. My goal is to help entities improve processes related to current grid challenges, risks, and of course standards and compliance, while also emphasizing that complacency is the enemy of continuous improvement. I hope to make entities aware of how RF can help you achieve your improvement goals by highlighting our resources and tools. In the end, our goal is to instill a culture of continuous improvement, not only for the sake of grid reliability, security, and resilience, but for the success of your organization.

February 2021’s Winter Storm Uri showed us that even an area of the country such as Texas can get hit with extreme cold weather that causes generators to fail. The below-freezing temperatures and swirling winds were a far cry from the typically 60-degree highs and 30-degree lows historically seen in the winter months in Texas.

NERC’s 2023 State of Reliability Overview states that while the bulk power system was reliable throughout 2022, “extreme weather events continue to pose the greatest risk to reliability due to the increase in frequency, footprint, duration, and severity.” And NERC’s 2023–2024 Winter Reliability Assessment notes that the grid has suffered five extreme events in the past 11 years, the two most notable being Winter Storms Uri in 2021 and Elliott in 2022.

In this article, we will discuss how a continuous improvement mindset is a great way to approach NERC’s cold weather Standard EOP-012, as well as winterization preparedness and best practices by taking a look at RF’s Cold Weather Winterization Program.

EOP-012 and Continuous Improvement

Continuous improvement is usually thought of as an important but voluntary endeavor. However, the requirements in NERC Standard EOP-012-1, which covers extreme cold weather preparedness and operations, deliver the best of both worlds: compliance to improve grid reliability, and continuous improvement to increase grid resilience.

The development of this standard came about as a result of the cold weather events of Winter Storms Uri, Elliott, and other cold weather events over the last several years. Two examples of its requirements are paraphrased below:

- Implementing freeze protection measures that provide capability to operate for a specified period at extreme cold weather temperatures.

- Periodically reviewing and inspecting whether generating units have proper freeze protection measures and developing a corrective action plan when needed (note that EOP-011-2 includes mandatory annual inspection and maintenance requirements).

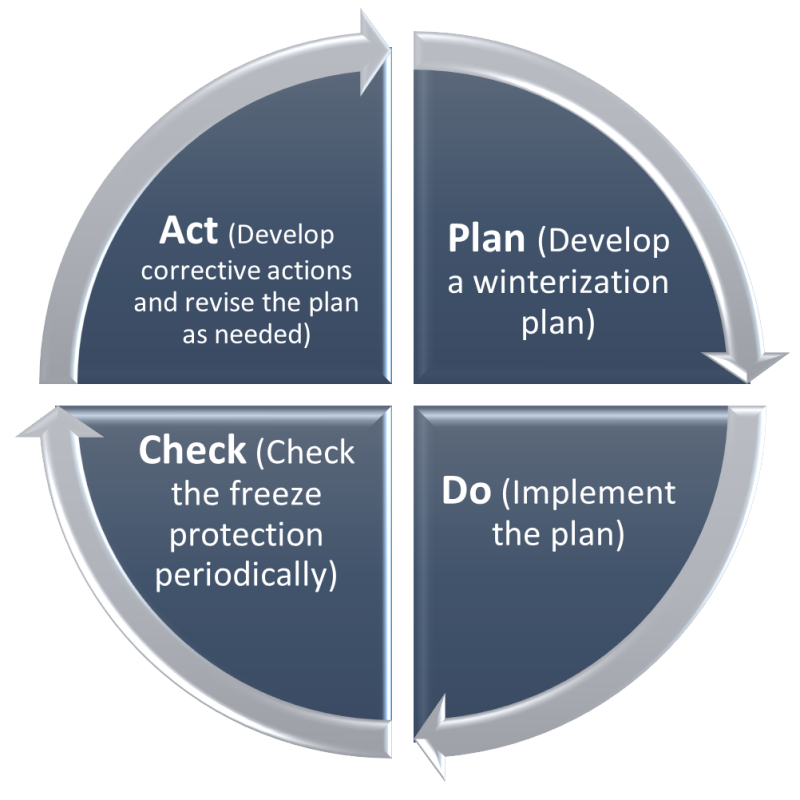

These requirements translate well to the most basic continuous improvement philosophy, called the “PDCA model”: Plan-Do-Check-Act. The standard includes planning and developing a winterization program, implementing the program, reviewing the state of freeze protection measures and generation assets, and correcting issues found during periodic reviews or as needed, thereby improving the program. The diagram below depicts an example of how the PDCA cycle could work for this standard:

RF Cold Weather Winterization Program

Another great way for entities to continuously improve their preparation for winter weather is to utilize RF’s Cold Weather Winterization Program. We have offered winterization visits for over a decade and recently ramped up this assistance, visiting 16 sites in the past year. Our experts will go on-site, visit your generating plant, and provide a custom report detailing best practices observed and recommendations for enhanced performance. Here’s how our process works:

- RF staff use NERC’s Generator Availability Data System (GADS) as a key data indicator for trends at generation plants in the RF footprint.

- We then identify which plants may be good candidates for on-site visits and evaluations.

- RF staff then sends the Generator Owners an introductory email about the Cold Weather Winterization Program, with an offer for RF to perform an optional site visit and evaluation.

- If the Generator Owner accepts the offered visit, RF will email a pre-visit survey to gather more information about the plant with questions asking about winterization plans; the types, locations, and winter protection of generation assets; and training.

- When on-site, the RF team will:

• Evaluate actions to determine the plant’s level of winter readiness

• Seek additional clarification of the plant’s responses to the RF Plant Winterization Survey

• Review the plant’s winterization plan

• Review records related to winterization plan implementation

• Participate in a walk-through of areas to evaluate winter readiness - After the visit, RF will provide a report with details on the equipment we reviewed, the team members involved, pictures of key equipment, and recommendations and positive observations.

Best practices for cold weather protection

Through our site visits to generating plants as part of the Cold Weather Winterization Program, RF has identified a slew of winterization best practices. Consider adopting these winter preparedness steps on your journey to continuous improvement:

- Meet and share information with other similar power plants (e.g. size and fuel type) in the region and around the country.

- Use indication lights and small thermometers in transmitter enclosure boxes to assist operators and indicate if heat trace systems are functioning properly.

- Increase a facility’s on-site supply of critical materials in case inclement weather interrupts suppliers from being able to replenish them as scheduled.

- Perform tabletop exercises to prepare personnel for responding to off-normal events, such as a frozen critical transmitter.

- Enclose equipment sensitive to cold weather events (such as air compressors) in either permanent or temporary structures.

- Stage emergency equipment for easy access when needed (e.g., have temporary space heaters quickly accessible in case of emergency).

- Gather information and lessons learned from previous winter seasons and formalize this process with documentation and sign-in sheets, etc., so the process is consistent in case of staffing changes.

- Create and use checklists that provide specific details of heat-tracing and instrument transmitters inspections. The checklist could include the specific panel name, location, and associated drawings and operational inspection results. This provides plant personnel with the necessary guidance and consistency for routine operations during cold weather.

Final thoughts

Complacency can cause issues in any industry. In the electric utility world, an absence of continuous improvement initiatives may adversely impact grid reliability and resilience, which can become apparent during extreme weather events that stress the grid.

Participating Generating Owners have all done a great job securing our grid from these events in just the last year as viewed from the 2023-2024 results of RF’s winterization visits. In 2023-2024, the RF region experienced a significantly lower frequency of outages due to cold weather compared to past years. We consider this a testimony to these entities’ hard work and their implementation of lessons learned from previous cold weather events.

It is important to institutionalize these improvements – don’t get complacent. Ensure that your facility complies with EOP-012 for reliability, but also strive to go above and beyond through continuous improvement efforts to increase resilience and security. Extreme weather events will keep happening and one can never be sure of the magnitude and damage severe weather may cause. By adopting these best practices, we will be more ready tomorrow.

To participate in a future winterization visit from our subject matter experts, please contact RF’s Entity Engagement group at entityengagement@rfirst.org or request an Assist Visit via our website.

Reference documents

The following are just a handful of many references regarding winterization:

- NERC alerts on the NERC website – e.g., Cold Weather Preparations for Extreme Weather Events III.

- Reliability Guideline Generating Unit Winter Weather Readiness— Current Industry Practices–Version 4

- Cold Weather Training Materials – as mentioned in the article, training is important to improve personnel knowledge for effective plant winterization.

- 2023 ERO Reliability Risk Priorities Report

- 2023–2024 Winter Reliability Assessment

- February 2021 Cold Weather Outages in Texas and the South-Central United States

- FERC, NERC Release Final Report on Lessons from Winter Storm Elliott